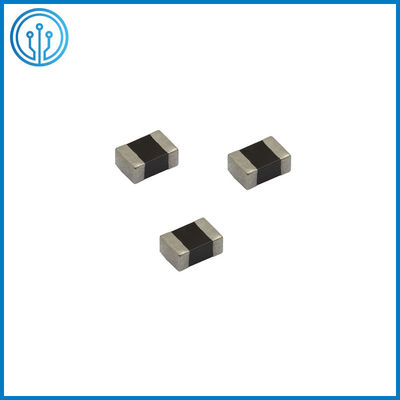

Taped In Reel 0805 100K Power NTC Thermistor 5% 4250 Surface Mount Thermistor

Product Details:

| Place of Origin: | Dongguan,China |

| Brand Name: | AMPFORT |

| Certification: | ROHS,REACH,UL |

| Model Number: | QN0805X104J4250FB |

Payment & Shipping Terms:

| Minimum Order Quantity: | 8000 Pieces |

|---|---|

| Price: | TBA |

| Packaging Details: | Tape, 4000pcs per reel |

| Delivery Time: | 10 workdays |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 1000,000,000 Pieces Per Month |

|

Detail Information |

|||

| Product Name: | Multilayer NTC Thermistor | Mounting Type: | Surface Mount |

|---|---|---|---|

| Temperature Range: | -40℃~+125℃ | Resistance: | 100 KOhm |

| B 25/50: | 4250±1% | B25/85: | 4310K |

| Dimension: | 0805 (2012 Metric) | Tolerance: | 5% |

| High Light: | Taped In Reel Power NTC Thermistor,0805 100K Power NTC Thermistor,5% 4250 surface mount thermistor |

||

Product Description

Taped In Reel High Accuracy 0805 Monolithic Multilayer NTC Thermistor 100K 5% 4250

I Description Of The Multilayer NTC Thermistor 0805

Standard Surface Mount NTC Thermistor available in the 0805 package.

NTC (Negative Temperature Coefficient) thermistors, which are typically composed of metal oxides, are manufactured to take on the form of disks, rods, chips and other shapes. A more common shape, the SMD (surface mount device), is widely used in standard reflow soldering processes. The different values and tolerances offered by the industry allow many renditions of package sizes within the dimensional constraints of an EIA standard. Although the SMD EIA standard specifies a maximum component height, in most cases a minimum is not, allowing the manufacturer greater flexibility in offering different values within an NTC. This bulletin will focus on the methods and materials recommended for component attachment either through hand soldering for prototype construction or reflow/wave soldering operations for normal production.

![]()

II Application Of The Multilayer NTC Thermistor 0805

· Temperature sensing, control and detection

· Temperature compensation of transistors, IC’s and crystal oscillators in mobile

· Consumer electronics

· Automotive electronics

· LCD controls

· Office automation equipment

· Communication equipment

· IT equipment

· Mobile devices

· Battery packs

· Battery chargers

· Hybrid ICs

· AV equipment

III Dimensional Drawing Of The Multilayer NTC Thermistor 0805 (unit:mm)

![]()

IV Main Techno-Parameters(In static air) Of The Multilayer NTC Thermistor 0805

| P/N | Resistance(25℃) | B Value(25/50℃)(K) | B Value(25/85℃)(K) | Operating Current (25℃)(mA) | Dissipation Factor (mW/℃) | Thermal Time Constant (s) |

| (kΩ) | ||||||

| QN0805X102F3650FB | 1 | 3650±1% | 3700 | 1.4 | 2 | <5 |

| QN0805X152F3950FB | 1.5 | 3950±1% | 3987 | 1.1 | ||

| QN0805X222F3450FB | 2.2 | 3450±1% | 3500 | 0.9 | ||

| QN0805X222F3950FB | 2.2 | 3950±1% | 3987 | 0.9 | ||

| QN0805X302F3450FB | 3 | 3450±1% | 3500 | 0.75 | ||

| QN0805X302F3950FB | 3 | 3950±1% | 3987 | 0.75 | ||

| QN0805X332F3450FB | 3.3 | 3450±1% | 3500 | 0.7 | ||

| QN0805X332F3950FB | 3.3 | 3950±1% | 3987 | 0.7 | ||

| QN0805X472F3500FB | 4.7 | 3500±1% | 3545 | 0.65 | ||

| QN0805X472F3950FB | 4.7 | 3950±1% | 3987 | 0.65 | ||

| QN0805X502F3500FB | 5 | 3500±1% | 3545 | 0.63 | ||

| QN0805X502F3950FB | 5 | 3950±1% | 3987 | 0.63 | ||

| QN0805X682F3500FB | 6.8 | 3500±1% | 3545 | 0.55 | ||

| QN0805X682F3950FB | 6.8 | 3950±1% | 3987 | 0.55 | ||

| QN0805X103F3380FB | 10 | 3380±1% | 3435 | 0.44 | ||

| QN0805X103F3450FB | 10 | 3450±1% | 3500 | 0.44 | ||

| QN0805X103F3570FA | 10 | 3520 | 3570±1% | 0.44 | ||

| QN0805X103F3900FB | 10 | 3900±1% | 3935 | 0.44 | ||

| QN0805X103F3950FB | 10 | 3950±1% | 3987 | 0.44 | ||

| QN0805X153F3950FB | 15 | 3950±1% | 3987 | 0.36 | ||

| QN0805X223F3950FB | 22 | 3950±1% | 3987 | 0.3 | ||

| QN0805X223F4050FB | 22 | 4050±1% | 4100 | 0.3 | ||

| QN0805X333F4050FB | 33 | 4050±1% | 4100 | 0.24 | ||

| QN0805X473F4050FB | 47 | 4050±1% | 4100 | 0.2 | ||

| QN0805X473F3960FA | 47 | 3920 | 3960±1% | 0.2 | ||

| QN0805X473F4150FB | 47 | 4150±1% | 4210 | 0.2 | ||

| QN0805X503F4150FB | 50 | 4150±1% | 4210 | 0.19 | ||

| QN0805X683F4150FB | 68 | 4150±1% | 4210 | 0.16 | ||

| QN0805X104F3590FB | 100 | 3535 | 3590±1% | 0.14 | ||

| QN0805X104F3950FB | 100 | 3950±1% | 3987 | 0.14 | 2 | <5 |

| QN0805X104F4100FA | 100 | 4050 | 4100±1% | 0.14 | ||

| QN0805X104F4250FB | 100 | 4250±1% | 4310 | 0.14 | ||

| QN0805X154F4250FB | 150 | 4250±1% | 4310 | 0.11 | ||

| QN0805X154F4500FB | 150 | 4500±1% | 4582 | 0.11 | ||

| QN0805X224F4300FB | 220 | 4300±1% | 4343 | 0.08 | ||

| QN0805X224F4500FB | 220 | 4500±1% | 4582 | 0.08 | ||

| QN0805X334F3950FB | 330 | 3950±1% | 3987 | 0.07 | ||

| QN0805X334F4300FB | 330 | 4300±1% | 4343 | 0.07 | ||

| QN0805X474F4000FB | 470 | 4000±1% | 4045 | 0.05 | ||

| QN0805X474F4500FB | 470 | 4500±1% | 4582 | 0.05 | ||

| QN0805X684F4100FB | 680 | 4100±1% | 4135 | 0.03 | ||

| QN0805X684F4500FB | 680 | 4500±1% | 4582 | 0.03 | ||

| QN0805X135F4500FB | 1300 | 4500±1% | 4582 | 0.02 |

V Sample application: Temperature detection for microcontrollers

Microcontrollers of smartphones and other devices must be protected from overheating to ensure their operation reliability. The diagram below shows a microcontroller temperature protection circuit that employs a voltage-dividing circuit consisting of a combination of NTC thermistor and fixed resistors RS. When an overcurrent flows, the temperature of the NTC thermistor rises and its resistance decreases, thus suppressing the drive voltage of the microcontroller. In order to achieve effective temperature protection small SMD NTC thermistors and resistors are mounted either on the circuit board or the heat generating part.

Fig. 4: Temperature detection for microcontrollers

![]()

VI Advantages Of The Multilayer NTC Thermistor 0805

NTC thermistors are temperature-sensitive resistor elements using semiconductor ceramics with negative temperature coefficients (NTC). That means that the resistance decreases exponentially with rising temperature. The steeper the RT curve, the greater the change in resistance within a specified temperature range. With this property, they are often used as temperature sensors and also used as temperature protection devices for purposes such as temperature measurement and temperature compensation.

VII HAND SOLDERING Of The Multilayer NTC Thermistor 0805

Due to the nature of their materials and construction, NTC thermistors can be very brittle, requiring delicate handling, especially during hand soldering operations. Their composition makes them very prone to tensile stress anomalies while remaining relatively strong in compression. During a reflow soldering operation, the component body temp is allowed to rise gradually prior to solder reflow, however in a hand solder operation, there is typically no preheat and the component is subjected to a thermal shock which may result in a fractured component. If hand soldering is necessary, a greater than 150˚C temperature difference between the thermistor and the soldering iron is not recommended prior to solder iron contact. A pre-heat of the component should diminish any possibility of thermal shock occurring. If hand soldering for prototype purposes is required, ensure proper component preheat and low temp solder (max 230˚C) is used.

VIII REFLOW SOLDERING Of The Multilayer NTC Thermistor 0805

• AMPFORT SMDs are not suitable for mounting on flexible substrates or in configurations that may place loads on the body. Improper CTE matches or board flexing will result in failure of the device.

• Exposure to soldering heat induces an irreversible shift in the device base resistance, therefore rework is not recommended. This magnitude of this shift is dependent on the device, contact AMPFORT for more information.

• AMPFORT PTC surface mount devices are not suitable for high temp (>230˚C) soldering.

VIIII Frequently Asked Question FAQ

Q: Are you manufacturer ?

A: Yes, we are manufacturer and distributor of famous brand such as Littelfuse.

Q: Which city does your factory in ?

A: Dongguan City,Guangdong Province, China

Q: May i know your working time ?

A: Official working time is 8:00 ~ 12:00 AM, 1:30 ~ 5:30 PM.However, sales in our overseas department will do overtime working and 7x24hours online.

Q: Do you accept custom made ?

A: Yes, we are professional in customization model based on rich experiences and professional engineering.It’s helpful if you can provide drawing or detailed specification should be.

Q: May i know your lead time ?

A: Lead time is 7 days for standard model and exact lead time depend on detailed requirements if special model selected.

Q: May i receive samples before place order ?

A: Yes, generally samples is free but sample cost should be charged if quantity is too many ,product cost is too much or new mould fee required.

Q: What’s your payment terms ?

A: T/T, Paypal etc.

Q: What’s currency you can accept ?

A: Mainly US dollars and Chinese Yuan

Q: Does your package method safe for transportation ?

A: Yes, our package would be 10~1000pcs per plastic bag -> multiple bags per box -> multiple boxes per carton and it is safe for express/air/boat shipment.