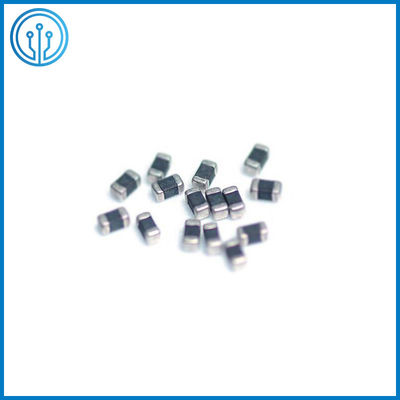

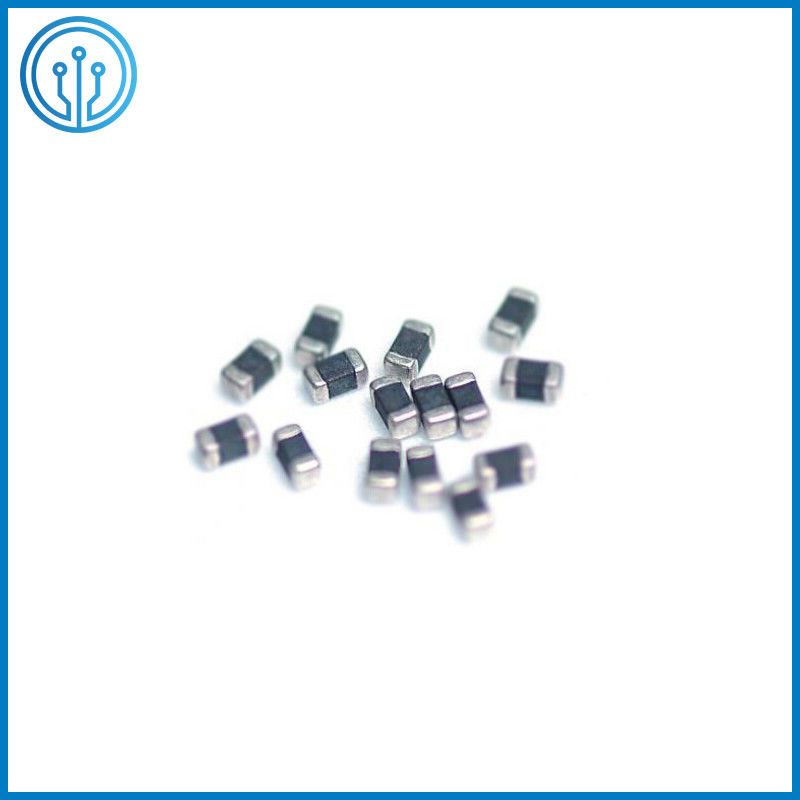

SMT 4250 NTC Thermistor 10k 1206 100K Negative Temperature Coefficient Resistor

Product Details:

| Place of Origin: | Dongguan,China |

| Brand Name: | AMPFORT |

| Certification: | ROHS,REACH,UL |

| Model Number: | QN1206 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 8000 Pieces |

|---|---|

| Price: | TBA |

| Packaging Details: | Tape, 2000pcs per reel |

| Delivery Time: | 10 workdays |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 1000,000,000 Pieces Per Month |

|

Detail Information |

|||

| Product Name: | SMT NTC Thermistor | Thermistor Case: | 1206 [3216 Metric] |

|---|---|---|---|

| Thermistor Mounting: | SMT/SMD | Resistance: | 10K /100 KOhm |

| B 25/50: | 3450/4250K | Package: | Cut Tape |

| MPQ: | 2000PCS PER REEL | Tolerance: | 1%-5% |

| High Light: | SMT ntc thermistor 10k,4250 ntc thermistor 10k,1206 100K negative temperature coefficient resistor |

||

Product Description

1206 100K 4250 Negative Temperature Coefficient SMT NTC Thermistor 3216 10K 3450

I Benefits Of The SMT NTC Thermistor 1206

NTC Thermistors are rugged, reliable, and stable, and they are equipped to handle extreme environmental conditions and noise immunity more so than other types of temperature sensors.

- Compact size: Packaging options allow them to operate in small or tight spaces; thereby taking up less real estate on printed circuit boards.

- Fast response time: The small dimensions allow for a quick response to change in temperature, which is important when immediate feedback is required.

- Cost efficient: Not only are thermistors less expensive than other types of temperature sensors; if the purchased thermistor has the correct RT curve, no other calibration is necessary during installation or over its operational life.

- Point match: The ability to obtain a specific resistance at a particular temperature.

- Curve match: Interchangeable thermistors with the accuracy of +0.1˚C to + 0.2˚C.

![]()

II Application Of The SMT NTC Thermistor 1206

• LCD compensation

• Battery packs

• Mobile phones

• CD players

• Heating systems

• Air-conditioning systems

• Temperature control of Switch Mode Power Supplies

• Compensation of pressure sensors

• Protection of power transistors in various electronic circuits

III Dimensional Drawing Of The SMT NTC Thermistor 1206 (unit:mm)

![]()

IV Main Techno-Parameters(In static air) Of The SMT NTC Thermistor 1206

| P/N | Resistance(25℃) | B Value(25/50℃)(K) | B Value(25/85℃)(K) | Operating Current (25℃)(mA) | Dissipation Factor (mW/℃) | Thermal Time Constant (s) |

| (kΩ) | ||||||

| QN1206X103F3450FB | 10 | 3450±1% | 3500 | 0.66 | 3 | <8 |

| QN1206X104F4250FB | 100 | 4250±1% | 4310 | 0.21 |

V Sample application: Temperature detection for LED lighting systems

In many portable electronic solutions, light-emitting diodes (LEDs) are widely used in general lighting and automotive lighting, where high brightness becoming increasingly popular. The solution is high-brightness LEDs (HBLEDs), which present numerous advantages over conventional lighting, but like any other semiconductor device they generate heat. One of the challenges is consequently thermal management. Generally speaking, high-quality LEDs are robust devices that can operate in excess of 100,000 hours when properly handled. However, high temperatures can significantly shorten their lifetime and negatively impact their brightness. To guarantee maximum lifetime, LED manufacturers usually recommend that current derating start at temperatures between 50 °C and 80 °C. Without temperature control the designer must ensure that the temperature never exceeds the recommended derating threshold of the LED, or limit current by a resistor to 57% of the maximum rating, which sacrifices the full LED brightness. That makes NTC thermistors the preferred choice for temperature sensing and control in lighting due to their attractive price/performance ratio. They enable LEDs to be used at full operating capability for a given lifetime, meaning higher current at lower ambient temperature and adapted lower current when temperature increases. This not only enhances LED lifetime, this also guarantees good lumen output. For the best performance the NTC sensing thermistor should be located close to the LEDs or in the hotspot of the LED board.

Different topologies can be used based on specific IC LED drivers. An NTC thermistor can operate in a resistor network where the sense voltage can indirectly control the LED current by influencing pulse-width modulation (PWM) ratio. Another option is shown in the diagram below. Here the NTC thermistor is used in the LED current sense branch to influence the feedback signal at higher temperatures. In this configuration the NTC must be connected to a constant voltage source, e.g. a reference output voltage provided by the driver.

Fig. 5: Temperature detection for LED lighting systems

![]()

VI Advantages Of The SMT NTC Thermistor 1206

NTC thermistors are temperature-sensitive resistor elements using semiconductor ceramics with negative temperature coefficients (NTC). That means that the resistance decreases exponentially with rising temperature. The steeper the RT curve, the greater the change in resistance within a specified temperature range. With this property, they are often used as temperature sensors and also used as temperature protection devices for purposes such as temperature measurement and temperature compensation.

VII HAND SOLDERING Of The SMT NTC Thermistor 1206

Due to the nature of their materials and construction, NTC thermistors can be very brittle, requiring delicate handling, especially during hand soldering operations. Their composition makes them very prone to tensile stress anomalies while remaining relatively strong in compression. During a reflow soldering operation, the component body temp is allowed to rise gradually prior to solder reflow, however in a hand solder operation, there is typically no preheat and the component is subjected to a thermal shock which may result in a fractured component. If hand soldering is necessary, a greater than 150˚C temperature difference between the thermistor and the soldering iron is not recommended prior to solder iron contact. A pre-heat of the component should diminish any possibility of thermal shock occurring. If hand soldering for prototype purposes is required, ensure proper component preheat and low temp solder (max 230˚C) is used.

VIII REFLOW SOLDERING Of The SMT NTC Thermistor 1206

• AMPFORT SMDs are not suitable for mounting on flexible substrates or in configurations that may place loads on the body. Improper CTE matches or board flexing will result in failure of the device.

• Exposure to soldering heat induces an irreversible shift in the device base resistance, therefore rework is not recommended. This magnitude of this shift is dependent on the device, contact AMPFORT for more information.

• AMPFORT PTC surface mount devices are not suitable for high temp (>230˚C) soldering.

VIIII R-T Characteristic Curves Of The SMT NTC Thermistor 1206

![]()

X Frequently Asked Question FAQ

Q: Are you manufacturer ?

A: Yes, we are manufacturer and distributor of famous brand such as Littelfuse.

Q: Which city does your factory in ?

A: Dongguan City,Guangdong Province, China

Q: May i know your working time ?

A: Official working time is 8:00 ~ 12:00 AM, 1:30 ~ 5:30 PM.However, sales in our overseas department will do overtime working and 7x24hours online.

Q: Do you accept custom made ?

A: Yes, we are professional in customization model based on rich experiences and professional engineering.It’s helpful if you can provide drawing or detailed specification should be.

Q: May i know your lead time ?

A: Lead time is 7 days for standard model and exact lead time depend on detailed requirements if special model selected.

Q: May i receive samples before place order ?

A: Yes, generally samples is free but sample cost should be charged if quantity is too many ,product cost is too much or new mould fee required.

Q: What’s your payment terms ?

A: T/T, Paypal etc.

Q: What’s currency you can accept ?

A: Mainly US dollars and Chinese Yuan

Q: Does your package method safe for transportation ?

A: Yes, our package would be 10~1000pcs per plastic bag -> multiple bags per box -> multiple boxes per carton and it is safe for express/air/boat shipment.