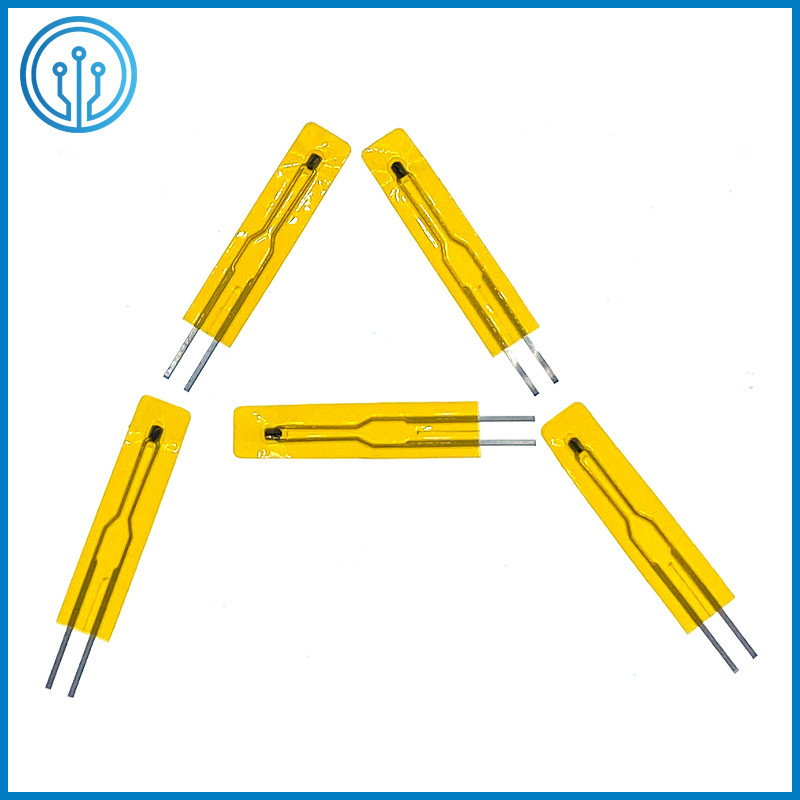

10K 3950 Low Profile Thin Film NTC Thermistor For Printer

Product Details:

| Place of Origin: | DONGGUAN,CHINA |

| Brand Name: | AMPFORT |

| Certification: | ROHS |

| Model Number: | MF55 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000PCS |

|---|---|

| Price: | 0.15USD Per Piece |

| Packaging Details: | Bulk |

| Delivery Time: | 10 workdays |

| Payment Terms: | T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 10,000,000pcs per week |

|

Detail Information |

|||

| Name: | Thin Film NTC Thermistor 10K 3950 | Rated Zero Power Resistance: | 5k Ω~500k Ω |

|---|---|---|---|

| Allowance Tolerance: | ±1%,±2%,±3%,±5% | Range Of B Value: | 3270-4750k |

| Operating Temperature: | -40 ~ +125 Deg | Total Length: | 25mm |

| High Light: | Low Profile Thin Film NTC Thermistor,10K 3950 Thin Film NTC Thermistor,10K 3950 Thermistor For Printer |

||

Product Description

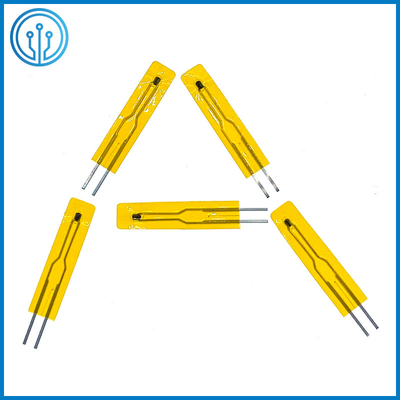

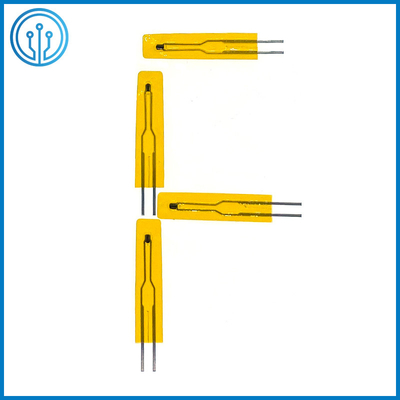

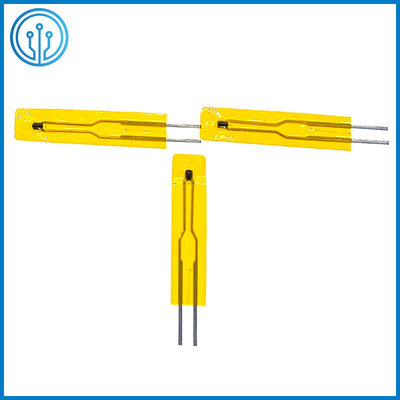

Fast Thermal Response Low Profile Thin Film NTC Thermistor 10K 3950 For Printer

Overview Of The Low Profile Thin Film NTC Thermistor 10K 3950

1) R25(Ω): 5K~500K

2) [Product Features] High sensitivity, fast heat induction, good stability, and high reliability

3) [Product use] Computers, printers, household appliances

4) Film type thermistors can reach up to 200°C, and are mainly used for temperature measurement, detection and control: such as air conditioners, microwave ovens, electric fans, electric heaters, rice cookers, induction cookers, hair dryers, etc.

5) Temperature detection and compensation of automatic office equipment, such as copiers and printers.

Introduction Of The Low Profile Thin Film NTC Thermistor 10K 3950

MF55 series film temperature measurement NTC thermistor is a new product that our company have recently researched, and it is made by whole-newly technique,and it has the viture of novel configuration and good security and good coherence. It can be used in such applications as temperature measurement and control and compensation.

ApplicationsOf The Low Profile Thin Film NTC Thermistor 10K 3950

◎ Compurter

◎ Printer

◎ Household Appliance

Features Of The Low Profile Thin Film NTC Thermistor 10K 3950

1. Suitable for narrow spaces

2. Fast response time

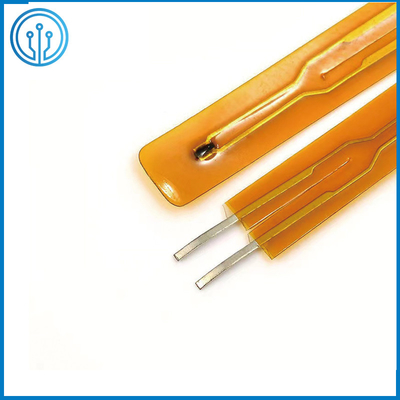

3. Flexibility and easy welding

4. Thin film coating, excellent insulation and heat resistance

5. Sensitive to the environment

6. Length options: 25mm, 50mm

7. High stability

8. Comply with RoHS directive

Dimension Of The Low Profile Thin Film NTC Thermistor 10K 3950 (mm)

![]()

Main Techno-Parameter Of The Low Profile Thin Film NTC Thermistor 10K 3950

◎Rated zero power resistance(R25)∶5k Ω~500k Ω

◎Allowance tolerance of R25:±1%,±2%,±3%,±5%E

◎Range of B value(B25/50):3270-4750k

◎Allowance tolerance of (Label by Requirment) B-value±1%,±2%

◎Dissipation coefficient: 20.8mW/C(In Still Air)

◎Operating temperature :-40 ~ +125deg

◎Rated power:≤50mW

Specification Of The Low Profile Thin Film NTC Thermistor 10K 3950

MF55 103 F 3380 F

① ② ③ ④ ⑤

①MF55 fim temperature neasurement NTC thermistor

② Resistance:103.…10KΩ

③F:±1% G:2% H:3%J:5%

④B-valuc;3380K:3950K

⑤ Tolerunce of B value F:±1% G:±2%

| P/N | Resistance | Beta value | Operating temperature | |||

| R25 (KΩ) | Tol. | (25/50℃) | (25/85℃) | Tol. | (℃) | |

| (K) | ||||||

| MF55□502□3270A | 5 | ±1% ±2% ±3% ±5% |

3270 | ±1% ±2% |

-50~260 | |

|

MF55□502□3470A |

5 | 3470 | ||||

| MF55□103□3380A | 10 | 3380 | ||||

| MF55□103□3435B | 10 | 3435 | ||||

| MF55□103□3470B | 10 | 3470 | ||||

| MF55□103□3950A | 10 | 3950 | ||||

| MF55□103□3975B | 10 | 3975 | ||||

| MF55□203□3950A | 20 | 3950 | ||||

| MF55□303□3950A | 30 | 3950 | ||||

| MF55□473□3950A | 47 | 3950 | ||||

| MF55□503□3950A | 50 | 3950 | ||||

| MF55□104□3950A | 100 | 3950 | ||||

Precautions Of The Low Profile Thin Film NTC Thermistor 10K 3950

1). Do not bend the resistance wire frame at will to avoid the chip and the wire frame from falling off and cause poor resistance;

2). The temperature during soldering should not exceed 300℃, and the soldering time should not exceed 0.5 seconds;

3). Use a hot air gun for heat shrinkable tubing, and the temperature of the air gun should be controlled at about 120°C;

4). Use a constant temperature soldering iron when soldering, the tip of the soldering iron is flat, the resistor is held in one hand, and the wire in the other hand is used for butt welding, which can improve production efficiency and shorten the welding time;

5). Special reminder: Do not touch the chip (that is, the top of the resistor) with your hands !