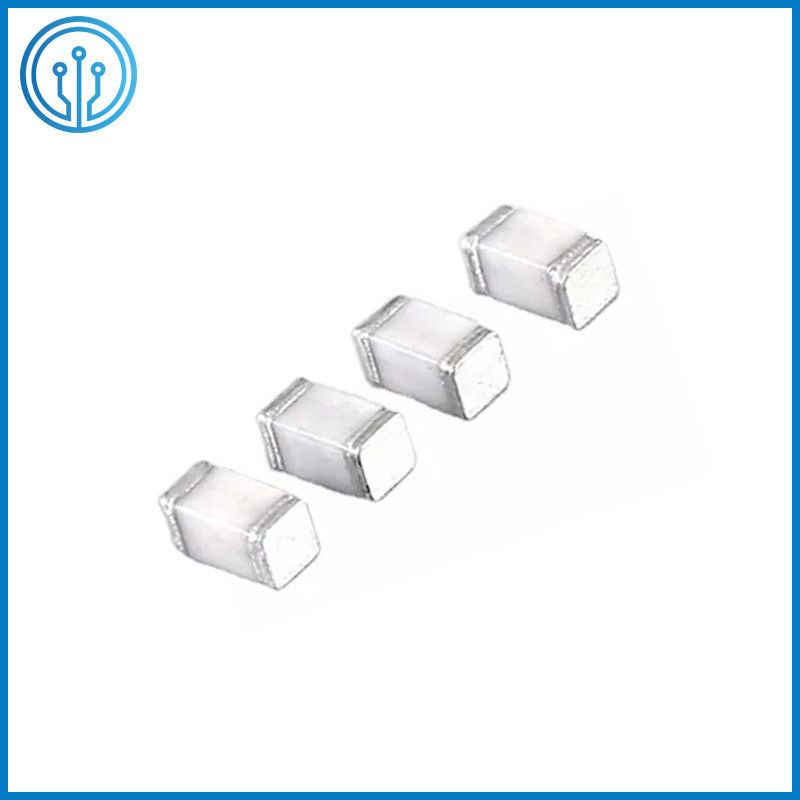

3216 1206 SMD Ceramic Gas Discharge Tube 150V 500A Glass Discharge Tube

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | AMPFORT |

| Certification: | ROHS,UL |

| Model Number: | 3DS150H |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2500 Pieces |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Tape,2500pcs per reel,50K per carton |

| Delivery Time: | 7-10 Workdays |

| Payment Terms: | T/T,Paypal |

| Supply Ability: | 90,000,000 Pieces Per Month |

|

Detail Information |

|||

| Name: | Ceramic Gas Discharge Tube 3216 150V 500A | Size: | 1206(3216) |

|---|---|---|---|

| DC Spark Over Voltage: | 150V±30% | Impulse Voltage: | ≤1100V |

| Insulation Resistance: | ≥100MΩ | Glow Voltage At 10mA: | ~60V |

| Arc Voltage At 0.2A: | ~10V | Weight: | 0.03g |

| Operation And Storage Temperature: | -40~+90°C | Surface Treatment: | Matte-tin Plated |

| High Light: | 3216 ceramic gas discharge tube,1206 SMD ceramic gas discharge tube,150V 500A glass discharge tube |

||

Product Description

2 Pole Surface Mount 1206 SMD Ceramic Gas Discharge Tube 3216 150V 500A

Description Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A

The two-pole SMD3216 series ceramic gas discharge tube produced by Ampfort Electronics is suitable for Coaxial, xDSL port, Internet port protection and surge protection for miniaturized ports. This series of products has the characteristics of small size, low capacitance value and strong current flow capacity. Volume: 3.2×1.6×1.6mm, voltage range: 90~600V, 8/20μs waveform can withstand 0.5kA surge protection.

Ampfort provides high-performance and small size packaging (DIP/SMD) gas discharge tubes with fast response speed and surge suppression capability, which reduces the risk of equipment damage, this is also a good choice for protecting devices from damaging by surge current caused by lightning, especially suitable for outdoor telecommunications equipment.

Feataures Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A

* Excellent response to fast rising transients

* Stable breakdown voltage

* GHz working frequency

* 8/20μs Impulse current capability: 500A

* Surface Mount package

* Non-Radioactive

* Ultra Low capacitance(<0.3pF) and insertion loss

* Lead-free compliant

* RoHS and REACH compliant

* Very Small Size(EIA 1206)

* Storage and operational temperature: -40~+90°C

Application Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A

* Ethernet, PoE, xDSL

* Cable modem, splitters, line cards

* Wireless antenna protection

* CATV equipment

* SPD

* Switching power supply

Specification Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A

a. Reference executive standard: ITU-TK12 Gbt9043-2008general Technical Requirements of Gas Discharge Tubes for the

b. Over-voltage protection of telecommunications installations

c. The maximum AC withstand current (50 Hz )is 1A and AC voltage shall be larger than the upper limit value of DC spark-over voltage during the test.

d. The electrode capacitance test frequency is 1MHZ and test voltage is 0. 5V

e. Operating and Storage temperature -40C~+85C

f. Packaging: Automaton taped 2500PCS per reel, 50000PCS per carton

| Catalog No. | DC Spark Over Voltage (100v/s)V | Impulse Spark Over Voltage (1kv/μs)V | Insulation Resistance MΩ | Electrode Capacitance 1MHz 0.5V PF | Impulse Discharge Current (8/20μs 10times) | AC Discharge Current (50Hz 1s 10times)A |

| 3DS090H | 090±30% | ≤900 | ≥100 | ≤1 | 0.5KA | 1A |

| 3DS150H | 150±30% | ≤1100 | ≥100 | ≤1 | 0.5KA | 1A |

| 3DS200H | 200±30% | ≤1100 | ≥100 | ≤1 | 0.5KA | 1A |

| 3DS300H | 300±30% | ≤1200 | ≥100 | ≤1 | 0.5KA | 1A |

| 3DS400H | 400±30% | ≤1300 | ≥100 | ≤1 | 0.5KA | 1A |

| 3DS500H | 500±30% | ≤1300 | ≥100 | ≤1 | 0.5KA | 1A |

Size Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A (mm)

![]()

GDT Benefits Of The SMD Ceramic Gas Discharge Tube 3216 150V 500A

• 10+ years of designing and manufacturing GDT devices

• Impulse current ratings (2 kA to 100 kA)

• Low capacitance and insertion loss

• Designs based on industry standards

• Switch-Grade Fail-Short technology available on some models

• Technical committee participation and leadership

• Custom device capabilities

• Lab facilities available for design verification of customer circuits as well as with testing capabilities for UL and Telcordia standards

Soldering Parameters - Reflow Soldering (Surface Mount Devices)

![]()

Surface mounted components (SMD) may exhibit a temporary increase in the DC spark-over voltage after the solder reflow process.The components will recover within 24 hours. There is no quality defect nor change in protection levels during the temporary change in DC spark-over voltage.

The SMD3216 series has been especially designed to meet data transmission protection requirements. The optimized design features a high level of protection against fast rising transients usually caused by lightning disturbances. For use in high frequency data lines, the series offers ultra low capacitances and shows only marginally signal losses up to high frequencies. The devices are extremely reliable and are able to withstand high surge currents without destruction.