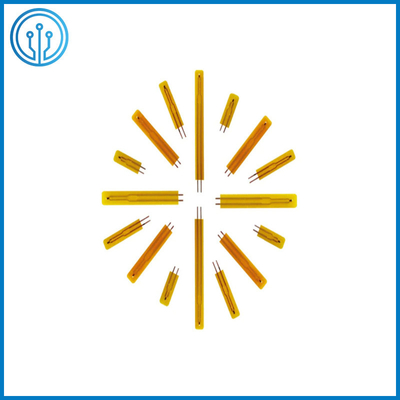

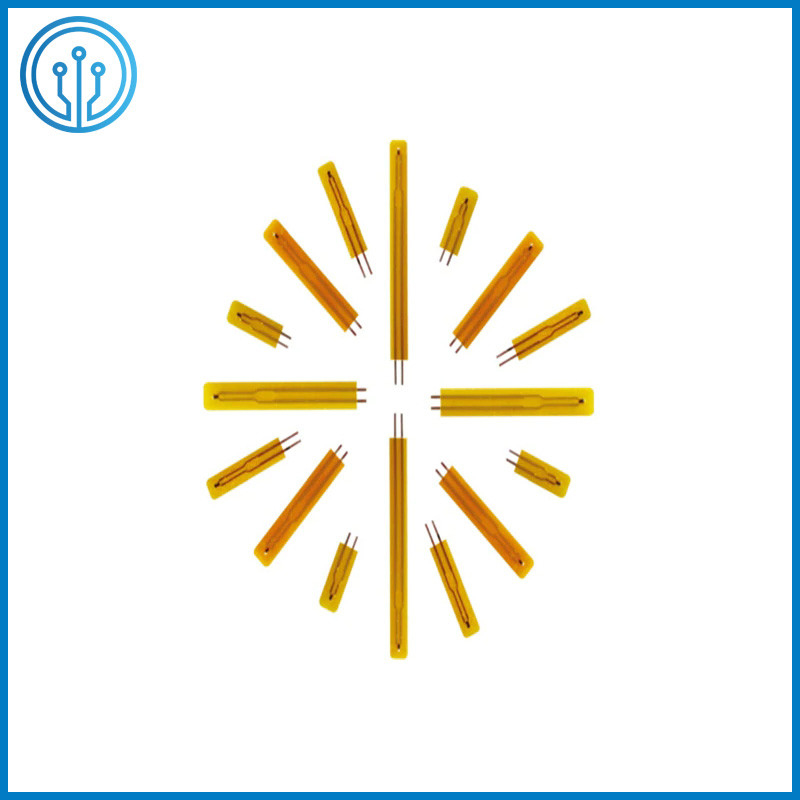

Surface Mount Low Profile NTC Thermistor 44mm 45mm

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | AMPFORT |

| Certification: | ROHS,REACH |

| Model Number: | MF55(44mm/45mm) |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000PCS |

|---|---|

| Price: | Consult |

| Packaging Details: | Bulk |

| Delivery Time: | 2 weeks |

| Payment Terms: | T/T |

| Supply Ability: | 20,000,000pcs per month |

|

Detail Information |

|||

| Name: | Negative Temperature Coefficient Thermistor | Total Length: | 44mm/45mm |

|---|---|---|---|

| Color: | Yellow | Tolerance: | 1%, 3%, 5% (subject To Availability) |

| Housing: | Polyimede Film | Frame: | Phosphorcopper |

| High Light: | Low Profile NTC Thermistor,NTC Thermistor 44mm,Negative Temperature Coefficient Thermistor 45mm |

||

Product Description

Surface Mount Low Profile NTC Negative Temperature Coefficient Thermistor 44mm 45mm

Description Of The NTC Negative Temperature Coefficient Thermistor

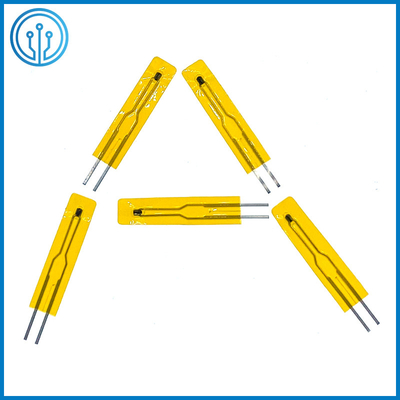

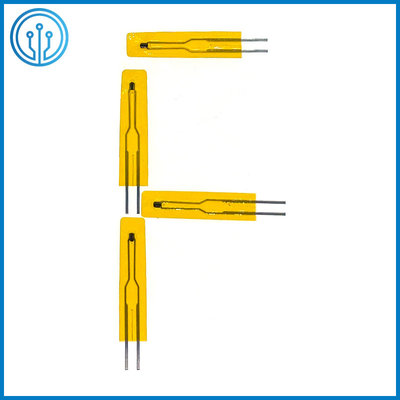

Ampfort has released a new Thin Film NTC Thermistor. The Thin Film NTC Thermistor are frequently used for applications where space is a concern and standard design are not thin enough. With a typical thickness of 0.9mm max offers the solution engineers have been looking for. They are an ideal choice for precise temperature measurement between flat surfaces where quick time response is critical. The thermistor chip is loaded between 2 conductors then sandwiched with polyimide insulation. This provides excellent moisture resistance, along with flexibility. All the usual benefits of thermistors where sensitivity to temperature change is paramount.

Features Of The NTC Negative Temperature Coefficient Thermistor

• Insulated membrane packaged,with fast thermal induction and high sensitivity.

• Good stability and high reliability.

• Good insulating property.

• High resistance precision.

• Safe in use.

• Small in volume,light in weight and firm in structure, applicable to automatic installation.

Purpose Of The NTC Negative Temperature Coefficient Thermistor

• Temperature measurement.

• Temperature control.

• Temperature compensation.

Application Of The NTC Negative Temperature Coefficient Thermistor

Computer, printer and electric family appliances.

1. Heater, Warmer, Automobile air conditioners, Refrigerators, Freezers,2. Water heaters, Gas boiler, Electric kettles, Wall-hung gas boiler, Water dispensers,

3. Toaster, Microwave oven, Air dryer, Roasting pan, Induction cooker, Electric hot plate,

4. Iron, Garment steamer, Hair straighten, Coffee maker, Coffee pot,

5. Rice cooker, Incubator temperature control, Egg boiler, etc.

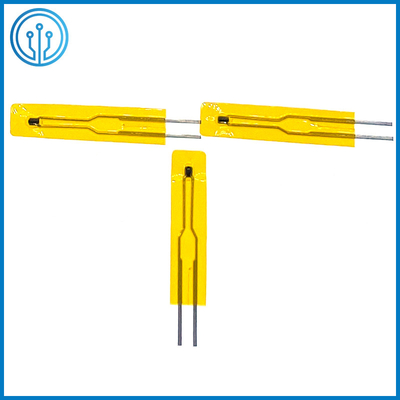

Dimensional Drawing Of The NTC Negative Temperature Coefficient Thermistor (mm)

![]()

![]()

Precautions Of The NTC Negative Temperature Coefficient Thermistor

• Do not bend the resistance coil holder lest the resistance deviates due to the shake-off of chips and coil holder.

• keep the temperature under 300℃ at soldering and not more than 0.5 seconds for soldering.

• Use hot air gun for heat shrinking tubing and keep the air gun at about 120℃ in temperature.

• When soldering, use constant temperature iron, with one hand holding the resistor, the other holding electric wires for butt-welding to improve the productivity and shorten the soldering time.

• Special notice: never touch the chip (the top of resistor) with hand.

Main Technical Parameters Of The NTC Negative Temperature Coefficient Thermistor

| Parameters | Parameter range | Test conditions | |

| R25(nominal resistance) | 10K Ω~ 100K Ω | Constant temperature 50℃± 0.05 ℃ | |

| Allowed R25 deviation(%) | ± 1 ,± 2 ,± 3 ,± 5 | Constant temperature 25 ℃± 0.05 ℃ | |

| B25/50(material coefficient) (thermal sensitive index ) | 3380K. 3950K | Constant temperature 25 ℃± 0.05 ℃ Constant temperature 50℃± 0.05 ℃ | |

| Allowed B25/50deviation(%) | ± 0.5 ,± 1 ,± 2 | Constant temperature 25 ℃± 0.05 ℃ Constant temperature 50℃± 0.05 ℃ | |

| δ(dissipation factor) | ≥ 0.7 mw/ ℃ | In still air | |

| τ(thermal time constant) | ≤ 5S | In still air | |

| TA(working temperature) | -30 ℃ ~ + 125 ℃ | ||

| PN(rated power) | ≤ 25 mw | ||

Warehouse Storage Conditions of Products

Storage Conditions:

1. Storage Temperature: -10℃~+40℃

2. Relative Humidity: ≦75%RH

3. Keep away from corrosive atmosphere and sunlight.

Period of Storage: 1 year

![]()