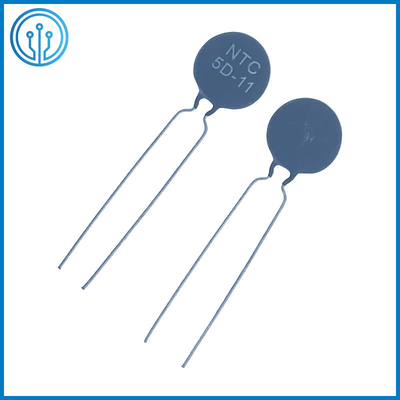

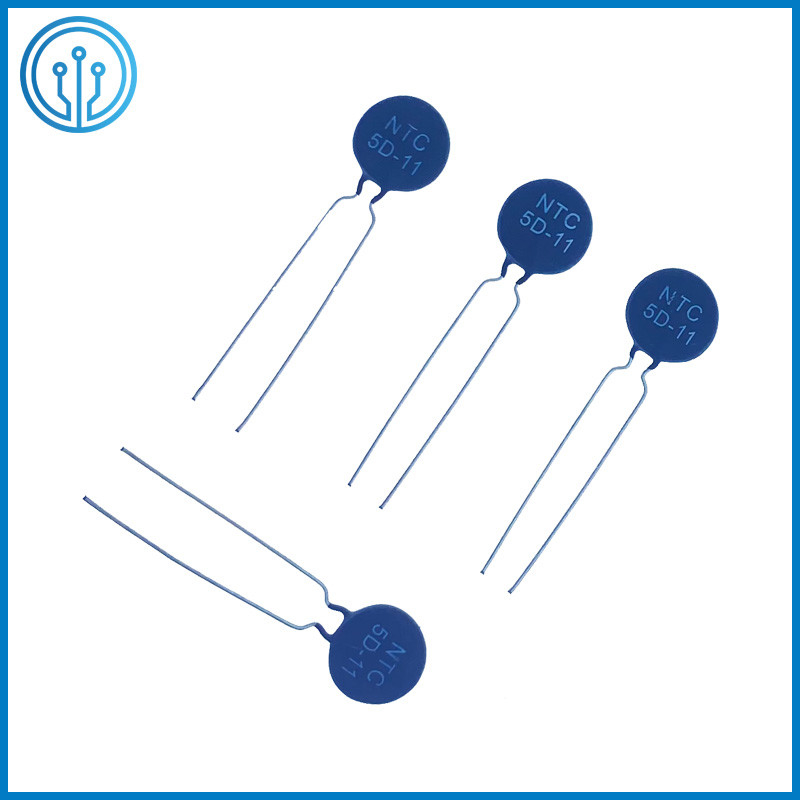

Directly Heated HEL MF72 Negative Temperature Coefficient Thermistor 5R 4A 5mm

Product Details:

| Place of Origin: | Guangdong,China |

| Brand Name: | HEL |

| Certification: | UL/CUL/CQC/TUV |

| Model Number: | MF72 5D-11 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10000PCS |

|---|---|

| Price: | 0.04~0.05 USD/PC |

| Packaging Details: | Bulk,500nos/polybag,1500 pcs per inner box,9000 pcs per carton |

| Delivery Time: | 5 workdays |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100KKPCS Per month |

|

Detail Information |

|||

| Name: | Negative Temperature Coefficient Thermistor | Dmax: | 13mm |

|---|---|---|---|

| Tmax: | 6mm | Pitch: | 5mm |

| R25: | 5Ω | Max Current: | 4A |

| Residual Resistance: | 0.16Ω | Beta: | 2700k |

| High Light: | 4A Negative Temperature Coefficient Thermistor,5mm Negative Temperature Coefficient Thermistor,TUV Power NTC Thermistor |

||

Product Description

Directly Heated HEL MF72 Negative Temperature Coefficient Thermistor 5D-11 5R 4A P=5mm

Application Of The Negative Temperature Coefficient Thermistor

- Switching power-supply,switch power,ups power

- Electronic energy saving lamps electronic ballast and all kinds of electric heater

- All kinds of picture tubes, monitors

- Bulb and other lighting lamps

- Agency Approvals

UL/CUL :E319959

CQC :10001052520

TUV :NO.B 001617 0001 Rev. 02

Size Of The Negative Temperature Coefficient Thermistor

![]()

| P/N | Dmax | Tmax | d ±0.05 |

F ±1 |

Straight Lead Wire Lmin |

| 5D-11 | 13 | 6 | 0.75 | 7.5/5 | 20 |

Materials Of The Negative Temperature Coefficient Thermistor

| Coating | Modified phenolic resin |

| Lead | CP Wire |

| Coating color | Black |

Electrical performance Of The Negative Temperature Coefficient Thermistor

| P/N | R25 (Ω) |

Max steady state current(A) |

Residual resistance (Ω) |

Dissipation coefficient (mw/℃) |

Thermal time constant |

Max allowed Use capacity value 240V/120V(μF) |

B value (K) |

Work temperature (°C) |

UL/CUL | CQC | TUV |

| 5D-11 | 5 | 4 | 0.16 | 14 | 50 | 470/1800 | 2700 | -40~ +175 | pass | pass | pass |

Thermistor has a good development prospect

Thermistors are widely used in household appliances, electric power industry, communications, military science, aerospace and other fields. They are widely used because of their unique properties. They can not only be used as measuring components (such as measuring temperature, flow, liquid level, etc.) , can also be used as control components (such as thermal switches, current limiters) and circuit compensation components. The advantages of thermistors are:

1. Small in size, it can measure the temperature of voids, cavities and blood vessels in living organisms that cannot be measured by other thermometers;

2. Easy to use, the resistance value can be arbitrarily selected between 0.1 ~ 100kΩ;

3. Wide operating temperature range, normal temperature devices are suitable for -55℃~315℃, high temperature devices are suitable for temperatures higher than 315℃ (currently up to 2000℃), low temperature devices are suitable for -273℃~55℃;

4. Good stability and strong overload capacity;

5. The sensitivity is high, and its temperature coefficient of resistance is more than 10 to 100 times larger than that of metal;

6. It is easy to process into complex shapes and can be mass-produced.

These advantages make thermistors should be widely used, and the development prospects are extremely broad.

The relationship between the size of the NTC thermistor and the filter capacitor

The size of the NTC thermistor to choose is determined by the size of the filter capacitor. The size of the NTC thermistor is determined, and there are strict requirements on the size of the filter capacitor that is allowed to be connected. This value is also related to the maximum rated voltage. In power supply applications, the power-on surge is generated by the charging of the capacitor, so the capacity of the NTC thermistor to withstand surge current is usually evaluated by the allowable access capacitance under a given voltage value.

The size of the NTC thermistor is determined, and the maximum energy it can withstand has been determined. According to the energy consumption formula E=1/2×CV2 of the resistance in the first-order circuit, it can be seen that the allowable access capacitance value is the same as the rated value. The square of the voltage is inversely proportional. All in all, the larger the input voltage, the smaller the maximum capacitance allowed to be connected, and vice versa.

![]()