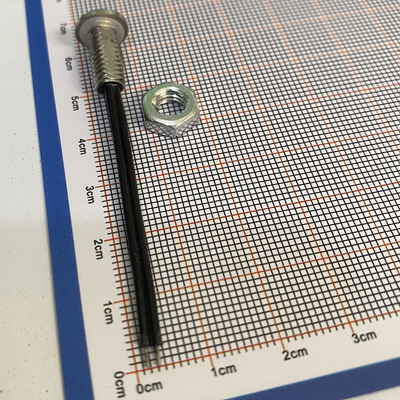

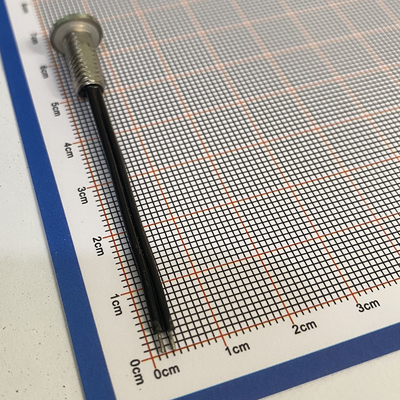

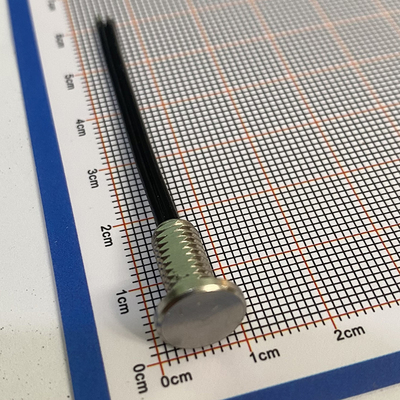

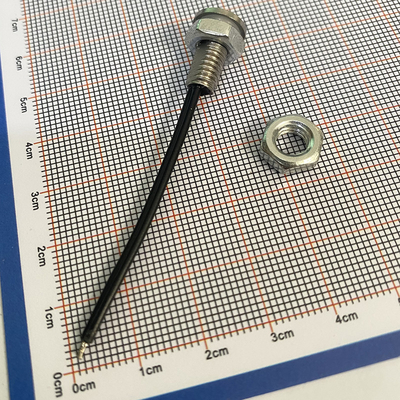

304 Stainless Steel NTC Thermistor Probe 10K 1% 3950 2651 26AWG 50mm For Bottle Warmer Temperature Measurement

Product Details:

| Place of Origin: | Dongguan,Guangdong,China |

| Brand Name: | AFTNTC |

| Certification: | ROHS |

| Model Number: | CWF103F3950M6L50ST |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 7-10 Workdays |

| Payment Terms: | T/T |

| Supply Ability: | 100KKPCS PER MONTH |

|

Detail Information |

|||

| Name: | NTC Thermistor Probe | R(25℃): | 10KΩ±1% |

|---|---|---|---|

| B(25/50): | 3950K | Measuring Range: | -30~+105C |

| Housing: | 10*14-M6*1 Flat SUS Housing,side Cut | Cable: | UL2651 26# 105℃ |

| Nut: | M6 Zinc Plated Iron Nut | Gasket: | 8*1.5 Silicone Sealing Ring |

| Typical Application: | Bottle Warmer | Cable Length: | 50mm Or Custom Requirements |

| High Light: | 304 Stainless Steel NTC Thermistor Probe,10K NTC Thermistor Probe |

||

Product Description

304 Stainless Steel NTC Thermistor Probe 10K 1% 3950 2651 26AWG 50mm For Bottle Warmer Temperature Measurement

Description

Baby bottle warmer can improve the efficiency of the entire heating process and avoid nutrient loss caused by overheating through NTC thermistor. NTC thermistor can improve the efficiency of the entire heating process and avoid the loss of nutrients caused by excessive heating. Considering the high requirements of baby bottle warmer for accurate temperature, thermistor generally choose the miniature insulated lead NTC thermistor produced by Ampfort Electronics Co., Ltd., which has the following advantages:

![]()

First, high accuracy, assist the baby bottle warmer to improve the accuracy of working temperature;

Second, excellent sensitivity, timely and rapid response, improve the work efficiency of the baby bottle warmer;

Third, the stability is great, the placement of the miniature insulated lead NTC thermistor can reduce the influence of ambient temperature on the baby bottle warmer when it works.

Typical Applications

Bottle warmer, Tea kettle, Water heater

Main Technology Parameters

| Item | Ratings |

| Rated zero-power resistance R25 | 10Kohm |

| Tolerance of rated zero-power resistance R25 | ±1% |

| Rated B-value B25/50 | 3950K |

| Tolerance of rated B-value B25/50 | ±1% |

| Cable | UL2651 26# 105℃ Black double line L=50±5mm(Exposed) |

| Terminal | Stripped and tinned 3mm |

| Nut | M6 zinc plated iron nut *2 |

| Operating temperature range | -40℃~+105℃ |

| Gasket | φ8*1.5 Silicone sealing ring*2 |

Specification of CWFSX01034FAB1500

![]()

Application of NTC Thermistor in Baby Bottle Warmer

In recent years, scientific parenting has reduced anxiety and brought convenience to most new parents, and the emergence of some practical small household appliances has made parenting more efficient and simple, the baby bottle warmer is a prominent representative of it. The temperature control of the baby bottle warmer is mainly through the NTC thermistor, which can keep the breast milk, drinking water, rice cereal, brewed milk, etc. within a certain temperature range, which is convenient to feed the infant at any time.

![]() Most of the baby bottle warmers on the market have a temperature adjustment function, which is aided by NTC thermistor, which brings convenience to users and provides a comfortable feeding experience for infants. When user places the bottle in the baby bottle warmer and presses the start button, the MCU (Micro Control Unit) starts to work, controlling the heating circuit to heat the bottle. The heating circuit feeds the real-time temperature back to the micro control unit through the NTC thermistor, and transmits the temperature data to the LED display in time, so that user can know the current temperature of the baby bottle at any time. Taking the appropriate feeding temperature of 45℃ as an example, when user sets this temperature point as the target temperature, the micro control unit will control the heating circuit through the drive relay to start working, and the NTC thermistor will monitor the temperature of the bottle in real time and feed it back to the micro control unit. When the thermistor monitors that the temperature of the bottle reaches the target temperature, the data is fed back to the micro control unit, which controls the heating circuit to stop heating and enter the holding state.

Most of the baby bottle warmers on the market have a temperature adjustment function, which is aided by NTC thermistor, which brings convenience to users and provides a comfortable feeding experience for infants. When user places the bottle in the baby bottle warmer and presses the start button, the MCU (Micro Control Unit) starts to work, controlling the heating circuit to heat the bottle. The heating circuit feeds the real-time temperature back to the micro control unit through the NTC thermistor, and transmits the temperature data to the LED display in time, so that user can know the current temperature of the baby bottle at any time. Taking the appropriate feeding temperature of 45℃ as an example, when user sets this temperature point as the target temperature, the micro control unit will control the heating circuit through the drive relay to start working, and the NTC thermistor will monitor the temperature of the bottle in real time and feed it back to the micro control unit. When the thermistor monitors that the temperature of the bottle reaches the target temperature, the data is fed back to the micro control unit, which controls the heating circuit to stop heating and enter the holding state.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()