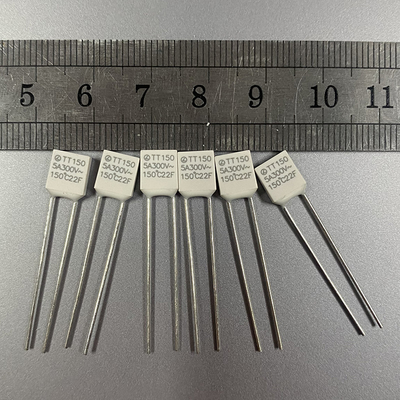

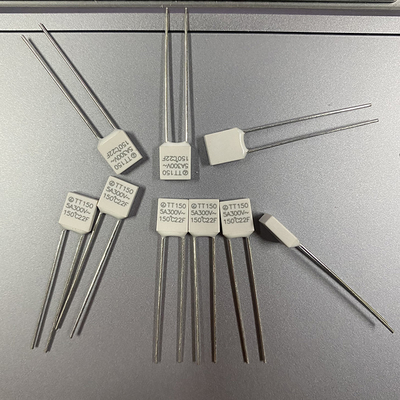

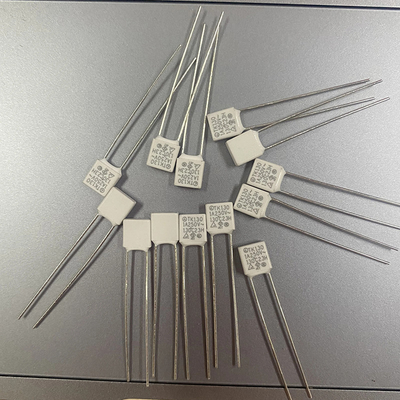

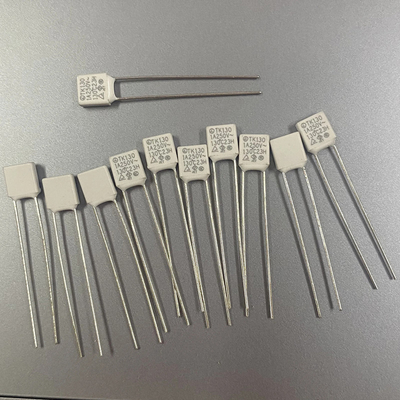

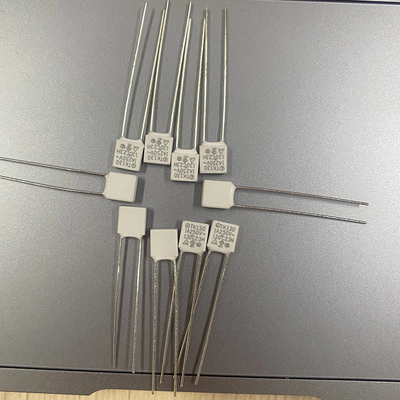

Plastic Square Shell TT 5A 250V 300V Defrost Thermal Fuse 76-150C For Steam Iron Hair Dryer Kettle Refrigerator

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | CNAMPFORT |

| Certification: | TUV,PSE,KTL,CCC |

| Model Number: | TT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5000pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Bulk |

| Delivery Time: | 2 Weeks |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 10KKPCS PER MONTH |

|

Detail Information |

|||

| Name: | Thermal Fuse For Kettle | Rated Functioning Temp. (Tf): | 76 ~ 150 ℃ |

|---|---|---|---|

| Rated Current (Ir): | 5A | Rated Voltage (Ur): | 250 / 300 VAC |

| Mounting Style: | Through Hole | Termination Style: | Radial |

| Applications: | Lamps,Switched-Mode Power Supplies | TUV (Germany): | R50525109 |

| PSE (Japan): | JET5359-32001-2022/23/01/02/03 | KC (Korea): | SU05026-23010/11/22 |

| CCC (China): | 2021000205000005 | Standard: | GB/T 9816 |

| High Light: | Steam Iron Defrost Thermal Fuse,Plastic Square Shell Defrost Thermal Fuse,250V 300V Defrost Thermal Fuse |

||

Product Description

Plastic Square Shell TT 5A 250V 300V Defrost Thermal Fuse 76-150C For Steam Iron Hair Dryer Kettle Refrigerator

![]()

Description

Alloy Thermal-Link / Alloy Thermal Cutoff (ATCO) is defined as a non-resettable protective device functioning one time only. It is widely used in electrical equipment. ATCO is mainly consist of fusible alloy, flux resin, case, sealant and lead wires. Normally, fusible alloy is jointed to the two lead wires. Under abnormal conditions, when the temp. reaches to the fusing temp. of ATCO, the fusible alloy melts and quickly retracts to the two lead wire ends with the aid of the flux resin and disconnects the circuit completely.

Features

- Plastic Case

- Non-Resettable

- High Accuracy of Functioning Temp.

- RoHS & REACH Compliant

Application

- Lamps

- Switched-Mode Power Supplies

- Home Electrical Appliances

- Power Strips

- Batteries

TT Specification

![]()

Safety Approvals

| Approvals | Temperature Range | Certification No. |

|

UL & cUL (America): (Canada): Standards: UL 60691 Standards: CAN-CSA-E60691 |

76~150℃ | Pending |

|

TUV(Germany): Standards: EN 60691 |

76~150℃ | R50525109 |

|

PSE(Japan): Standards: J60691 |

76~150℃ | JET5359-32001-2022(76℃) JET5359-32001-2023(86℃) JET5359-32001-2001(102℃,115℃) JET5359-32001-2002(125℃,130℃,136℃) JET5359-32001-2003(145℃,150℃) |

|

KTL(Korea): Standards: K60691 |

76~150℃ | SU05026-23010(76℃,86℃) SU05026-23011(102℃,115℃) SU05026-23022 (125℃,130℃,136℃,145℃,150℃) |

|

CCC(China): Standards: GB/T 9816 |

76~150℃ | 2021000205000005 |

Ordering info

| P/N | Tf(℃) | Fusing-Temp.(℃) | Th(℃) | Tm(℃) | Ir(A) | Ur(Vac) | In 8/20μs 15 Times (kA) |

Imax 8/20μs 1 Time (kA) |

| TT76 | 76 | 73±2 | 48 | 180 | 5 | 250 | 2 | 4 |

| TT86 | 86 | 83±2 | 58 | 180 | 5 | 250 | 2 | 4 |

| TT102 | 102 | 99±2 | 77 | 180 | 5 | 250 | 3 | 6 |

| TT115 | 115 | 112±2 | 87 | 180 | 5 | 250 | 3 | 6 |

| TT125 | 125 | 122±2 | 98 | 180 | 5 | 250 | 3 | 6 |

| TT130 | 130 | 127±2 | 100 | 180 | 5 | 250 | 3 | 6 |

| TT136 | 136 | 133±2 | 102 | 180 | 5 | 250 | 3 | 6 |

| TT145 | 145 | 141±2 | 118 | 180 | 5 | 250 | 3 | 6 |

| TT150 | 150 | 147±2 | 122 | 180 | 5 | 250 | 3 | 6 |

![]()

![]()

![]()

![]()

Soldering

Hand-Soldering

1. Soldering should be carried out according to Table T-1.

2. The thermal element of ATCO is fusible alloy with low melting point, which is jointedwith ATCO lead wires. Improper soldering operation (too high soldering temp. , toolong soldering time, too short lead wire etc.) may transfer more heat to the thermalelement and ATCO may open in advance.

3. When soldering conditions are more severe than those listed in Table T-1, a heat sinkfixture should be used between soldering point and ATCO body.

4. When soldering, please do not pull / push or twist ATCO body or lead wires.

5. After soldering, let it naturally cool for longer than 20 seconds. During cooling, nevermove the ATCO body or lead wires

Wave Soldering

The wave soldering parameters as Table T-2, for reference only, when ATCO is for practice use, you need to do somevalidation experiments. For example, using X-RAY to see the fusible alloy of ATCO whether damage after wave soldering.

Usage

1. When atmosphere pressure is from 80 kPa to 106 kPa, the related altitude shall be from 2000 meters to - 500 meters.

2. Operating voltage less than rated voltage of ATCO, operating current less than rated current of ATCO.

3. Do not touch the ATCO body or lead wires directly when power is on, to avoid burn or electric shock.

Replace

ATCO is a non-repairable product. For safety sake, it shall be replaced by an equivalent ATCO from the same manufacturer, andmounted in the same way.

Storage

Do not store the ATCO at the high temp., high humidity or corrosive gas environment, avoid influencing the solder-ability of thelead wires, the product shall be used up within 1 year after receiving the goods.

Installation

Make Sure the Temp. of Installation Position.

1. It is recommended that a dummy ATCO with inbuilt thermo-couple shall be used to determine the proper temp.

2. The terminal product should be tested to ensure that potential abnormal conditions do not cause ambient temp. to exceed theTm of the ATCO.

3. Mount the ATCO at the location where temp. rises evenly.

Installation position of mechanical performance requirements.

1. Do not locate the ATCO in a place where severe vibration always occurs.

2. Ensure that the lead wire is long enough, and avoid actions such as press, tensile or twist.

3. The seal or body of ATCO must not be damaged, burned or over heated.

Specification

| Tf ºC | G4A01 | Th ºC | Tm ºC |

| 72 | G4A01072C | 57 | 100 |

| 73 | G4A01073C | 58 | 100 |

| 77 | G4A01077C | 62 | 300 |

| 84 | G4A01084C | 69 | 220 |

| 91 | G4A01091C | 76 | 300 |

| 93 | G4A01093C | 78 | 300 |

| 98 | G4A01098C | 83 | 300 |

| 104 | G4A01104C | 89 | 200 |

| 110 | G4A01110C | 95 | 240 |

| 117 | G4A01117C | 102 | 240 |

| 121 | G4A01121C | 106 | 300 |

| 125 | G4A01125C | 110 | 185 |

| 128 | G4A01128C | 113 | 205 |

| 134 | G4A01134C | 119 | 205 |

| 141 | G4A01141C | 126 | 205 |

| 144 | G4A01144C | 129 | 300 |

| 152 | G4A01152C | 137 | 205 |

| 158 | G4A01158C | 143 | 240 |

| 167 | G4A01167C | 152 | 210 |

| 172 | G4A01172C | 157 | 310 |

| 184 | G4A01184C | 169 | 240 |

| 190 | G4A01190C | 175 | 350 |

| 192 | G4A01192C | 177 | 210 |

| 205 | G4A01205C | 190 | 310 |

| 216 | G4A01216C | 200 | 450 |

| 229 | G4A01229C | 200 | 450 |

| 240 | G4A01240C | 200 | 450 |

| 257 | G4A01257C | 220 | 470 |

Electrical Rating Summary

| Series | G4 | G5 | |

| Agency | Resistive | Inductive | Resistive |

| UL/CSA | 21A/240VAC | 8A/250VAC | 20A/250VAC |

| 10A/250VAC | 14A/120VAC | 25A/120VAC | |

| 15A/120AC | 21A/240VAC | ||

| 5A/24VDC | 20A/277VAC | ||

| VDE | 10A/250VAC | 8A/250VAC | 20A/250VAC |

| CCC | 5A/24VDC | 8A/250VAC | 20A/250VAC |

| 10A/250VAC | |||

| PSE JET | 10A/250VAC | 15A/250VAC | |

MICROTEMP TCO Standard Dimensions

![]()

G4A00 has one short lead and one long lead.

G4A01 has 2 long leads.

Standard body 4.0 φ*14.7mm Diversion 1.0φ*14.2mm and 1.0φ*34.9mm named G4A00XXXC

Extended body 4.0 φ*14.7mm Diversion 1.0φ*33.2mm and 1.0φ*34.9mm named G4A01XXXC

Emerson Electric (T-O-D) authorized dealers to supply the original original Emerson fuse (hot melting fuse), G4 series global universal fuse, G4A00240C/G4A01240C, rice cooker electric iron and other electrical fuse. If you need more understanding, welcome to inquire:

Special description: The MicroteMP hot melting fuse (temperature fuse) produced by the American Emerson brand "Therm-O-DISC" thermal disc company provides customers with a very accurate and reliable upper limit temperature protection. When the working temperature exceeds the rated temperature of the thermal fuse, it can quickly interrupt the circuit to avoid the harm caused by overheating. It has established its unshakable flagship status in the same industry products. The Emerson series temperature fuse has a small size that detects the function of abnormal temperature and cuts off the circuit, and a strong temperature overheated fuse. It detects the temperature of abnormal temperatures of household or industrial electrical products and quickly cut off the circuit in a timely manner to prevent the effect of preventing the damage. This series of temperature fuse is installed with thermist particles (organic chemicals) materials into the metal shell for excessive heat numbers. Its specialty can cut off a large current (rated current) of 5A to 25A

MicroTemp hot melting fracture has 5 basic models:

G4: [G4 series thermal fuse] The G4 series Microtemp® hot melting fuse made by the American Emerson brand "Therm-O-DISC" thermal disc company. According to different product specifications, the contact capacity can reach AC250V 10A and AC120V 15A, respectively With DC24V 5A, it can provide reliable overheating protection. Among the products in the same industry, the G4 series Microtemp hot melt fracture has established its unshakable flagship position. The G4 series thermal fuse is widely used in various instrumental appliances and personal electrical appliances every year, providing a very precise overheating protection, and providing reliable backup protection for internal temperature controllers. The G4 series thermal fuse, as the protector of the electrical appliances, is also widely used in various office equipment, portable electric heaters and industrial equipment.

G5: The G5 series Microtemp hot melting fracture is specially designed and applied to high -current loads. Depending on the product specifications, the contact capacity can reach AC250V 20A, AC277V 20A, and AC120V 25A, respectively. The G5 series thermal fuse is very similar to the G4 series thermal fuse, but the interior uses different structural design, which can disconnect the circuit in time in the face of higher current loads. The G5 series thermal fuse can provide reliable overheating protection, which are mainly used in various electric heater and other high -current load devices.

The G6 series Microtemp thermal fuse, which is small in size and can quickly disconnect the circuit to provide reliable overheating protection. The contact capacity can reach the AC250V 16A. Compared with the double metal sheet temperature controller, the price has a more competitive advantage.

The G7 series Microtemp thermal fuse is specially designed to design in product equipment that is used for high -current loads but pursuing minimal volume. The G7 series thermal fuse is only 1/3 of the G4 or G5 series, and the contact capacity is AC250V 5A and DC24V 5A. It is mainly used in various transformers, motors, battery packs and electronic circuits.

The G8 series Microtemp thermal fuse, small body shape, can quickly disconnect the circuit, provides reliable overheating protection, the contact capacity can reach AC250V 25A and 277V 20A. Compared with the single trigger device of the dual -metal sheet, it has more prices in terms of price. Competitive Advantage. With its small volume (the same as the G4 and G5 series thermal fuses) and the advantages of installation and thermal reaction, it is widely used in various equipment.

The E series is specially named for ROSH in the early days. The characteristics are the same as the G series

Temperature:72℃ 73℃ 77℃ 81℃ 84℃ 93℃ 98℃ 104℃ 110℃ 117℃ 121℃ 125℃ 128℃ 134℃ 141℃ 144℃ 152℃ 158℃ 167℃ 172℃ 184℃ 190℃ 192℃ 205 ℃ 216 ℃ 229 ℃ 240 ℃

![]()

![]()

![]()

![]()